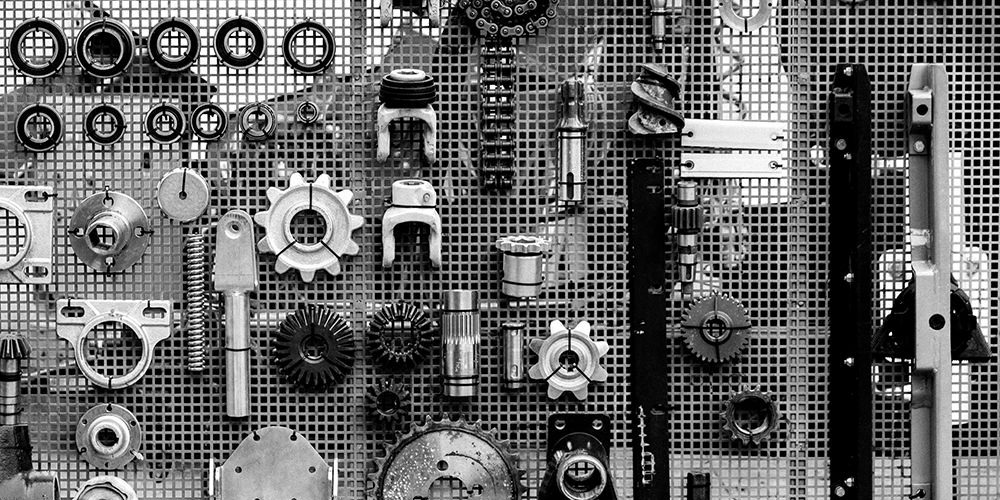

Progressive flame hardening is used for treating selected surface areas, typically on large parts such as gears, sprockets, cams, bearings & wheels.

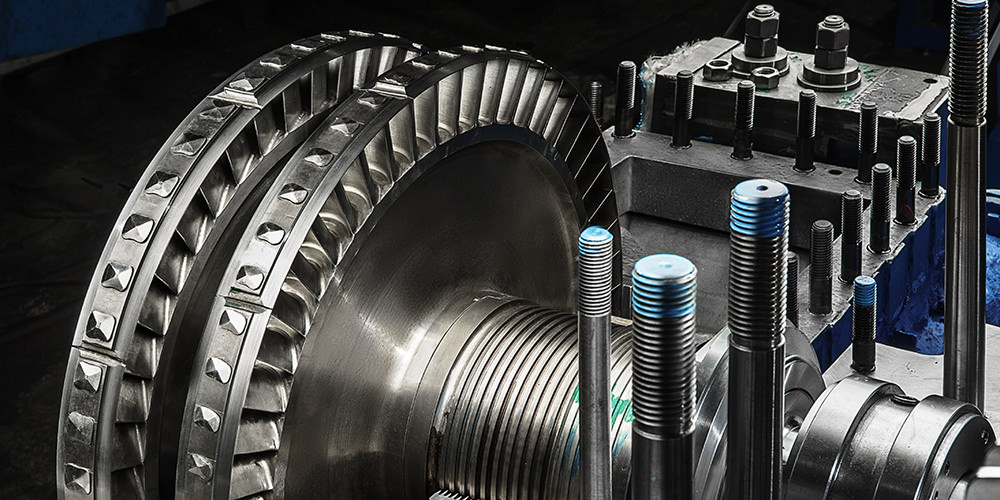

Spin flame hardening applies heat to specific portions of circular parts followed by quenching of the full part.

Combination progressive/spin techniques are applied to large shafts, pins and rollers to uniformily treat the surface across the length of the part.

Spot hardening can be used to harden specific areas of a part to improve wear resistance without embrittling the entire piece.

Induction heat treating methods employs electrical energy to apply heat to selected areas for both hardening and annealing parts.

Stress relieving, Straightening, Hardness Testing, Level II Die Testing, Case Depth Measurement, and more. Contact us to discuss your application.

We are proud to announce that we have merged with Vacu Braze, Inc - a specialty heat treatment facility in Bucks County Pennsylvania. Our equipment and services will be migrating to their new and expanded facility in 2017.